Retinning

Copper cookware restoration

Copper cookware restoration

When we take a candidate pan into our Lima, OH tin shop, our goal is not merely to re-line it, but to restore it to like-new condition. Restored copper is often even slightly better than new, as the copper has been “work-conditioned” and is therefore even more thermally efficient and energy diffusive than when it was first formed. If you’d like to know how the process unfolds, we’ve detailed it below.

When you’re ready to get going on restoration of your wares, the first step is to fill in our Work Order Form, which you can find right here.

Free Return Shipping

BCC quality retinning and restoration includes return Ground shipping in the US to any of the 48 contiguous States, as well as APO and FPOs. Return shipping to Alaska and Hawai’i are eligible for discounted USPS and UPS rates.

If there’s anything further you’d like to know, or if you have an unusual piece or situation, feel free to be in touch via the contact page.

Please note!

We specialize in hand-wiped molten retinning. Generally any copper piece that was originally tin electroplated cannot be relined by the wipe technique. This includes (but is not limited to) partially or fully enclosed kettles, most narrow-necked milk pots, most mokas or Turkish coffee pots, as well as dessert and gelatine moulds. We will have to return any piece that we believe would be damaged in the rigors of our restoration process. If you’ve any questions about your cookware’s eligibility, again, please be in touch with us.

For service on original tin plating, please search “Tin electroplating service”.

The first phase of the restoration process entails evaluating a candidate pan for mitigating factors, such as metal fatigue / embrittlement, “dinnerplating” and other fractures in handles, aluminum rivets and other potential problems about which the customer must be notified. We can usually repair or work around such issues, but they lie outside the straight-forward restoration process and may entail additional costs.

Very infrequently is a pan beyond saving, but the time to make that determination is before subjecting it to the rigors of the restoration process, when high heat and caustic exposures can damage porous or friable metals. Once a pan passes initial assessment it is no longer a candidate pan, rather it is now a project and is assigned a numbered metal tag to identify it through various phases of the restoration process.

Retruing curves, working out slight dents and tightening rivets are next. Superficial scratches and scrapes are removed using a fine emery wheel.

Both tin and nickel linings to copper cookware form a ceramic-like “intermetallic compound”, which occurs between the metal layers. Pure tin and nickel can be dissolved in concentrated acids (we use hydrochloric) that do not affect the copper, but often the intermetallic layer remains and has to be worked off the copper by hand. Other caustic agents such as muriatic acid are used to loosen and clean exterior carbonization (pitch-colored reduced carbohydrates).

The stripped and cleaned project pan is now painted with a pure lime paste on its exterior and handles to create a barrier layer during the tinning procedure, preventing molten tin from bonding anywhere other than to the interior of the pan body.

Tinning is actually the fastest part of the overall process. First the project is heated to upwards of 700℉ over an open forge. The pan body has to be kept hot as molten tin is ladled into it at 425℉ and wiped by hand to a uniform thickness and surface contour. As the tin crystallizes the temperature of the pan body is steadily lowered until the intermetallic compound “cures”, signaling the need to “quench” the process in cool water. From heated pan body to quenched and cured new tin lining takes less than 10 minutes for an average-sized pan.

The lime mask and caustic residues are removed with detergents and rinsed again in clean water. Handle joints, rivet heads and other tight angles are air-blasted to remove residual trace acids, which can form verdigris (copper corrosion) beneath handle bearing surfaces.

The clean pan is checked for edge blisters in the new tin, which are ground flush. A texturing wheel is used to abrade the surface of the copper and orient its crystalline grain in a single direction. Thereafter, 3 – 5 steps of successively finer polishing and buffing wheels are employed to leave the exterior with a mirror (“rouged”) finish.

Tight areas around handles are textured and polished by hand using jeweler’s rouge and polishing cloth.

Here’s everything you need to know about getting your copper cookware taken care of by BCC.

Here’s everything you need to know about getting your copper cookware taken care of by BCC.

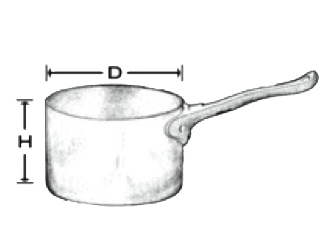

The price for our full service, described above, is $5.50 per linear inch, measured as 2 times the height plus the diameter. We can also restore a piece that is lined with stainless steel (provided the liner hasn’t delaminated from the base) but cannot re-line it. The price for restoration without relining is $3.50 per linear inch.

All BCC service pricing includes free Ground return shipping in the US to any of the 48 contiguous states, as well as APO and FPO addresses.

To get an estimate on the cost of restoring your pan (cleaning, etching, retinning and polishing), just enter the height of your pan wall and its diameter (or, in the case of irregular or oblong pans, the long axis) below. The output will be a close estimate of what we’ll charge for the service.

H (Height) equals 3.5 inches. Double that = 7 inches

D (Diameter) equals 7.5 inches = 7.5 inches

TOTAL = 14.5 inches

14.5 inches x $5.50 inch = $79.75

Our timeline for restorations is currently 10-12 weeks, with up to 1 additional week needed from late October through the end of a year. All restoration work is performed at our production molten tinning shop in Lima, Ohio.

Return freight will be from Lima via UPS insured. We cover return shipping costs and will always endeavor to reuse your original shipping box if we can (we’re big on recycling). If we need to provide new packaging materials, these vary by pan type and quantity, but usually run $8 for a single pan, and up to $20 for multiple pans or more than one box. We pack very carefully with recyclable materials and use high burst-strength boxes to ensure your beautifully restored cookware returns to you in good order.

When you’d like to proceed with restoring your wares, please complete this Work Order form. We will send you a follow-up email with specific packing and shipping instructions including a confirmation form to include with your shipment for tracking purposes.

We look forward to putting your beloved copper back to work good as new!

If you’re ready to get your cookware back in the game, just fill out our Retinning Work Order form to get started. Should you have further questions or would just like to talk it over, drop us a line anytime.