Every Item Completely Unique.

Every vessel Brooklyn Copper Cookware makes is spun from heavy copper and wipe-laid by hand with pure tin.

Every pan in the Brooklyn Copper Cookware range takes at least 8, and at most 11 hours to build, and is the singular effort of a small group of coppersmiths, tinsmiths and ironsmiths, all steeped in skills perfected centuries ago and once again available in America.

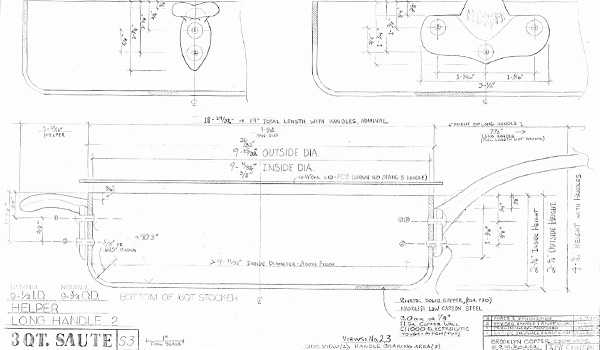

Designed on Purpose.

From the curve of the handles to the slope of the base, each and every element of Brooklyn Copper Cookware has been designed with a purpose. How BCC goes about design is substantially different from how most manufacturers develop new designs these days. Barbara Stork has some 25 years of experience designing castings. She may be one of the last designers of anything three-dimensional who neither knows nor wishes to know anything of computer-aided design. She draws all of our plans, elevations and designs by hand, modeling them in clay to create masters that go on to become our cookware tool sets.

Details Count.

Despite being best-of-class in nearly every dimension, there is nothing revolutionary about what we make. Copper cookware is one of humanity’s primal technologies, and BCC has not strayed from the basis of its success: Copper + Tin + Iron. Rather, we endeavor at every step to understand and honor these elemental materials and the process of bringing them together.

Up to 32 hands touch every piece of BCC, and every one of them is feeling for fit, finish and the resonance of unimpeachable quality. Our eyes have to see themselves clearly in everything we make before yours do.

There’s copper cookware, and there’s Brooklyn Copper Cookware.

Coppersmithing

The copper in Brooklyn Copper Cookware is a special crystalline formulation of copper called C12200 phosphorus deoxidized, which is minimally 99.93% pure. The remaining .07% is mostly silver and phosphorus. Our copper is also RoHS (Restriction of Hazardous Substances) Directive compliant, i.e., effectively lead, cadmium and mercury-free.

We finessed our sheet rolling so that the strongest possible bond between copper and tin would be the natural result. We take the time to “work toughen” our pan bodies so they will never sag or belly-out. We do this by listening to the metal as we work it, literally tuning it to the perfect “ring”.

It’s like making dinner; you get better results when you love how you do it.

Tinsmithing

Pure tin is as non-stick a cooking surface as can be found. Food lifts off pure tin much as it does from well-seasoned steel, but tin does not require seasoning – its crystalline structure is already very smooth (i.e., molecularly simple and well-ordered). Our “lab-grade” tin is even more certifiably pure than our copper, clocking in at 99.99+%.

Before hand-applying and wiping the tin lining, the pan’s base is heated to between 700 and 800℉ so the entire interior temperature remains above the 425℉ melting point of pure tin long enough for the entire surface to be wiped by hand. Once the tin is thickly and evenly distributed, the pan is immediately quenched to seize the tin’s crystalline structure within the etched copper and force a molecules-thin bronze-like intermetallic alloy to form between distinct elemental layers, bonding evenly to both.

High quality is a matter of timing, temperature and technique. Sound familiar?

Ironsmithing

We pour ductile iron (instead of the more common gray iron) so our handles “breathe” with their pans. The unique curves of our long handles are not merely beautiful, they use their material to manage heat transmission and maximize control. Our ear handles rest easily in your grip and ride just as easily on your “chops”. Unique flat cover Stang handles sit cooly up and off the heat column so you can fine-tune venting without cooking your fingers. Each handle is individually milled to fit the one-of-a-kind curves of its pan, and every solid-shank pure copper rivet is hand-set.

None of the tools for all this existed, so we made our own to make cookware on our own terms.