22 Feb For Everything a Season?

A curious meme has popped up on the interwebs regarding seasoning of non-stick pans, possibly because cast iron seasoning is on more peoples’ radars these days, but just as possibly because cookware that suggests it’s seasonable gets associated with cookware that is definitely seasonable, which ups the cachet of the former by imputing qualities of old-fashioned characteristic robustness of the latter.

Polytetrafluoroethylene (PTFE) and other non-stick surfaces, including most if not all “ceramic” or embedded silicate and colloidal types, are polymer based, meaning their bases are chained-up monomers, normally derived of hydrocarbons and mechanically bonded to the coarse, irregular metal surface of a pan. These polymers penetrate and form up inside the microscopic irregularities of the pan’s surface first, establishing the plastic-to-metal bond, and subsequent polymer layers are bonded over this to effect a uniform, flat, smooth working top coat. Polymers and metals are capable of forming neither chemical nor alloy bonds, rather, their bonds are entangled.

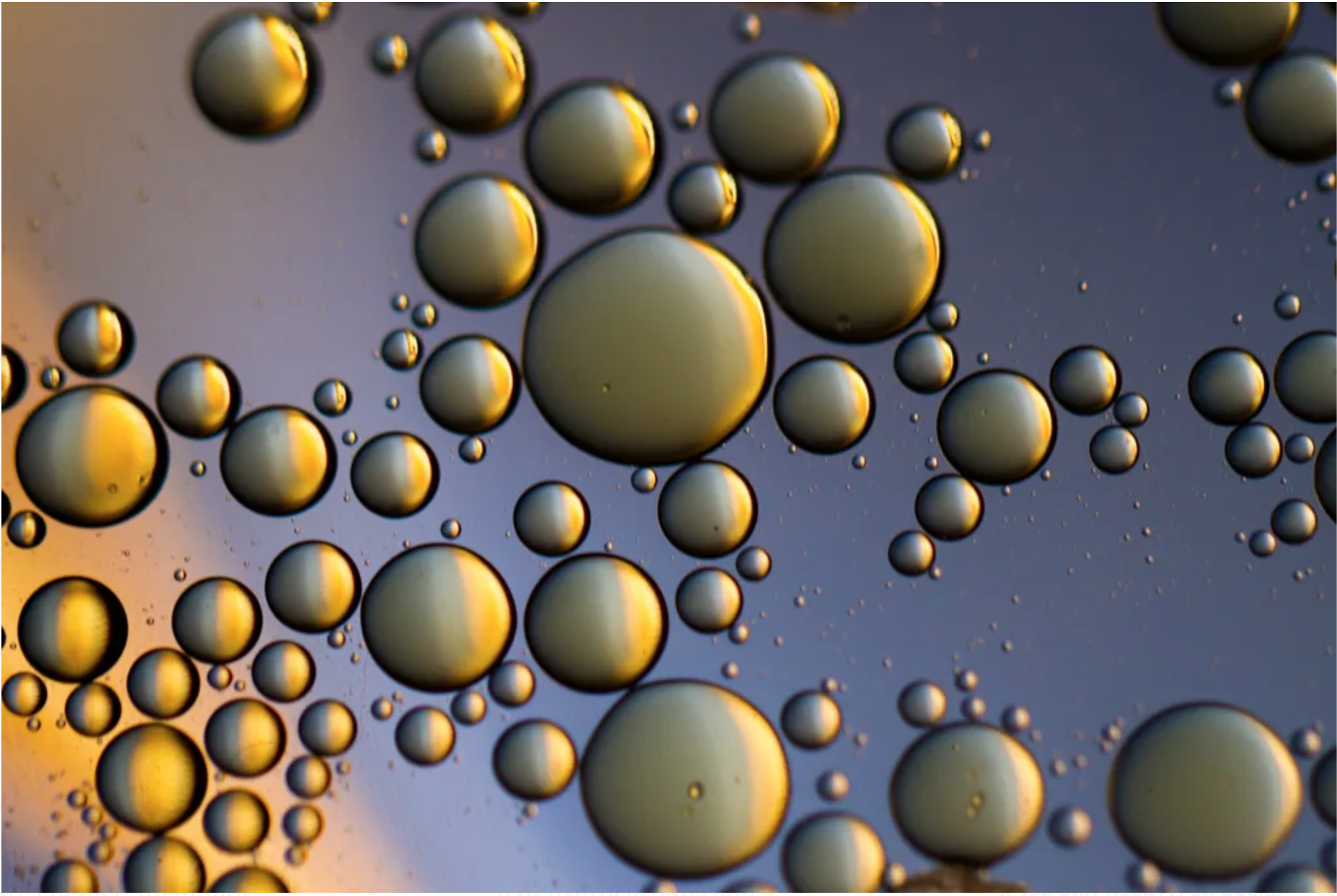

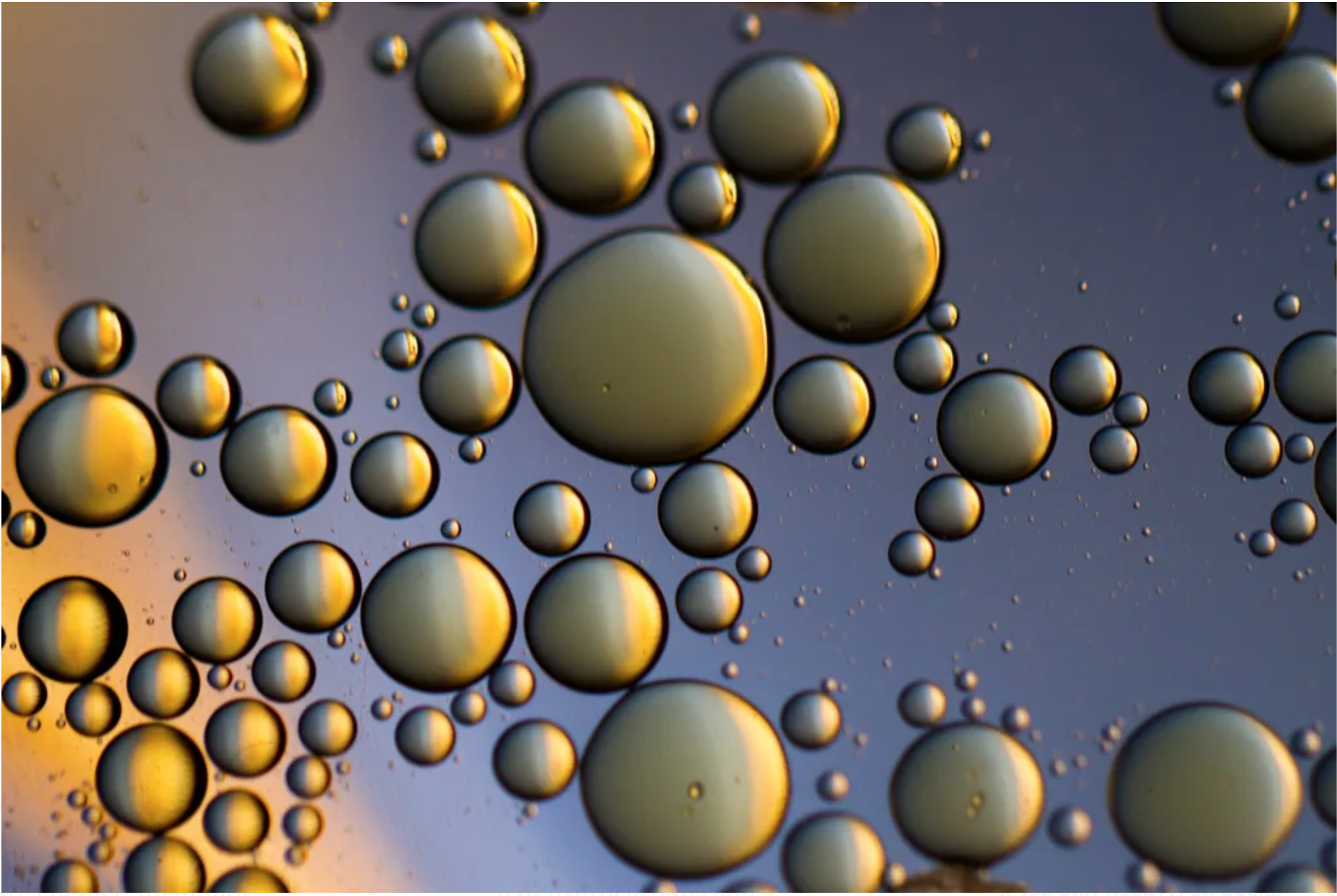

Pan seasoning with a cooking oil proceeds on the same basic principle, substituting (preferably) a seed oil (such as flax) for a hydrocarbon. Slow heating of a thin layer polymerizes the oil within the superficial micro structure of the pan, which, built up, results in first and foremost a protective layer for an iron or steel pan, and, with time and careful detergent-free cleaning, a solid, renewable low-stick working surface.

Two things are commonly observed about naked stainless steel — first, it’s sticky, and second, it does not season.

Apart from protecting pans that are readily subject to oxidative corrosion, seasoning requires a surface structure that can accommodate lipid polymerization. Stainless steel (SS) and aluminum do not. The crystalline structure of SS is very finely granular (owing to its multi-metallic alloyed composition, a key factor in the material’s poor thermal efficiency) and resists soft polymer chain growth on its surface. This also accounts for two things commonly observed about naked SS — first, it’s sticky, and second, it does not season. SS does, however, accept pre-polymerized coatings applied under high heat and pressure, which insinuate the polymer chains into the surface contour of a complex metal. This process can be used with PTFE, other polyfluoroalkyls (PFAs), Sol-gels, or any pre-polymerized lining, which will mechanically conform and harden into a pan’s surface.

Aluminum has a very regular and large crystalline structure (which accounts for its relatively high thermal efficiency) and offers little porosity in which a polymer could actively bond. Bare aluminum is, however, a very sticky cooking surface owing to a bunch of loose but complex chemical bonding potentials. For this reason it’s horrible to cook on directly, and is therefore popularly lined with non-stick polymer sheet. Like SS, under sufficient heat and pressure aluminum will anchor pre-polymerized material, in this case by agitating the metal’s crystalline structure and opening microscopic gaps into which polymers can then penetrate under pressure.

Both carbon steel and cast iron (gray and ductile) are highly porous with a relatively inefficient but open crystalline structure, and both accommodate active polymer formation and “interdigitation” (entanglement) easily and securely. These are realistically the only candidates for natural oil seasoning, as both have the requisite surface micro-structure.

Carbon steel and cast iron are realistically the only candidates for seasoning, both having the requisite surface micro-structure.

PTFE and other non-stick surfaces are, obviously, very smooth. All polymers resist bonding to other polymers and other chained substances, such as starches, sugars, proteins and other foods that chain into complexes from simpler states as they cook. This is the practical meaning of non-stick.

A non-stick pan has neither the surface characteristics nor the chemistry to accept seasoning when it’s new — this is why oils bead on non-stick surfaces. However, as such surfaces (quickly) age, they become dry and embrittled at the surface as much of what maintains the polymer bonds breaks down and outgasses with use. In the case of PTFE the byproduct of breakdown is perfluorooctanoic acid (PFOA), a documented carcinogen and ground water contaminant (be wary of manufacturer’s language in this regard: Non-stick surfaces are often touted as “made without PFOA”, which is true; PTFE is indeed made without PFOA. With the application of temperatures above 400℉ (gas range flame is ~3200℉ at the tip), PTFE makes PFOA sufficient to cause a range of maladies. Best practice is to never heat lined cookware empty).

It takes very little polymer degradation among “ceramic” non-stick linings to reveal embedded silicates, which then form a finely saw-toothed (hence very sticky) surface. These elements tend to disengage from their polymer lattice with stuck food that has to be loosened with increasing force, which in turn increases the rate of lining degradation. Pure PTFE-based linings, i.e., those without embedded silicates or other crystals, tend to degrade more slowly.

Degraded non-stick micro-contours could hypothetically be seasoned, i.e., interdigitate with an actively-forming polymer, however, the effort is likely futile as neither the polymer nor its metal substrate (aluminum or SS) are conducive to active polymerization.

More likely would be that the oils intended to season remain encapsulated in the surface irregularities and oxidize (polyunsaturated oils oxidize especially readily) to form an irregular lacquer over the damaged non-stick surface, which is nearly impossible to dissolve once it has formed. Owing to available oxygen bonding potentials, this lacquer tends to be very sticky — kind of an anti-seasoning. Solvents and propellents in spray oils (i.e., alcohol) tend to facilitate the lacquering process, promoting rapid oxidation of both the oils they propel, and oils infiltrating the decaying plastic surface of a pan, which causes rapid build up of the lacquer, or familiar “glaze,” on degraded non-stick surfaces.

Since it’s impossible to season a polymerized surface, not doing so has no bearing on its wear, longevity or working properties.